A fully Automatic Cell Counter for High Throughput Cell Culture Monitoring

Abstract

Accurate monitoring of cell density and viability in mammalian cell culture bioreactors is a longstanding challenge. Traditional methods rely on sampling and staining, limiting their applicability in small-scale bioreactors. The NORMA 4S analyzer, featuring lens-less technology, offers a breakthrough solution by enabling precise determination of cell concentration and viability without staining or dilution. This integration with high throughput microbioreactors automates measurements and ensures rapid results. Comparative studies confirm a strong correlation between NORMA 4S and the Beckman Coulter Vi-Cell XR. In conclusion, NORMA technology’s advantages, including low sample volume, label-free detection, and high repeatability, make it an ideal choice for small-scale bioreactors and high-throughput applications, effectively reducing batch-to-batch variations.

Introduction

Monitoring cell density and viability of mammalian cell culture bioreactors is a necessary task that still presents a number of remaining challenges. Traditional measure for cell count and cell viability still relies on sampling and staining protocol where the trypan blue exclusion method is performed once a day. While automatic cell counters have reduced the statistical error of the original manual method, daily sampling is still a challenge for small scale bioreactor because the sampled volume becomes significant.

NORMA analyzers integrate a new breakthrough method, based on the lens-less technology, for accurate determination of cell concentration and viability without staining, sample preparation, or dilution. The NORMA 4S is perfectly integrated with high-throughput micro-bioreactors allowing a full process automation. Tests have been performed on the NORMA 4S integrated to the high-throughput micro-bioreactors Sartorius Ambr® 15. Moreover, a comparative study between the NORMA 4S and the Beckman Coulter Vi-Cell XR showed a close correlation between our device and the reference counters.

Material & methods

1 - The NORMA 4S

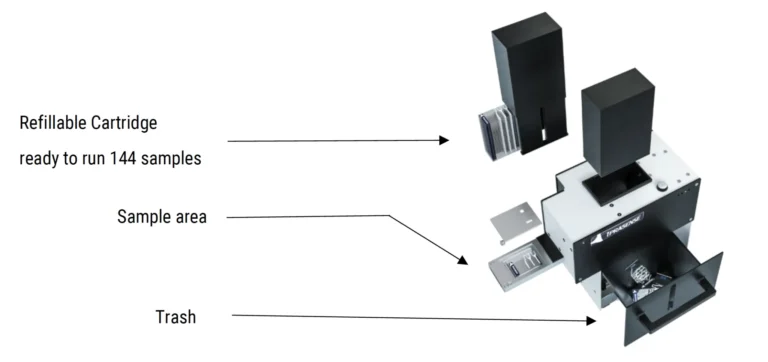

The NORMA 4S is composed of a refillable cartridge of 36 four-chamber slides allowing 144 samples to be made. A slide from the cartridge is automatically put on the sample area where you can drop your sample and start the measurement. When it’s done, the slide is thrown in the trash and a new one is ready to receive four other samples. The technology directly acquires the light diffraction properties of each individual cells through their hologram images without any objective, lens or focus settings. Living and dead cells have significant holographic patterns that can be distinguished and accurately counted. The measurements are analysed by the HORUS software. The NORMA 4S rapidly measures cell concentration and viability without compromising repeatability.

Figure 1 : NORMA 4S Overview

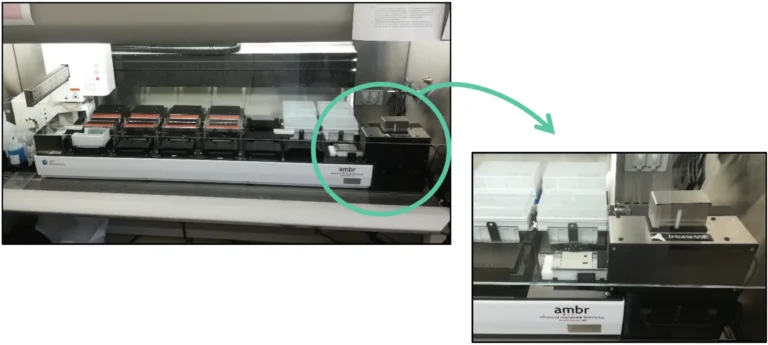

2 - The integration of the NORMA 4S into the high throughput micro-bioreactors Sartorius Ambr® 15

The NORMA 4S is fully adapted to the high-throughput automated micro-bioreactor, the Sartorius Ambr® 15. The NORMA 4S is placed to the right of the Ambr® 15. One complete measurement cycle is about 1 minute. The robotic arm opens and takes a few microliters from the bioreactor and dispenses the sample on the slide. Each slide is used for 4 independent samples. After delivering the sample, the arm disposes the used tips in the tip trash. The measurement slide is then automatically retracted by the NORMA 4S to perform the holographic measurement and immediately returns a new slide to the next measurement position.

To adapt the NORMA 4S to your Ambr® 15, all you have to do is program the robotic arm to deliver the samples in the NORMA 4S sample area. The position can be adjusted by adapting the standard protocol and by sharing folders between the Ambr® 15 and the NORMA 4S.

You can view the NORMA 4S integrated to the Sartorius Ambr® 15 in application via the replay of our Webinar in collaboration with Melissa Hill (Investigator, Biopharmaceutical Process Development, GSK).

Figure 2 : the NORMA 4S integrated into the Ambr® 15

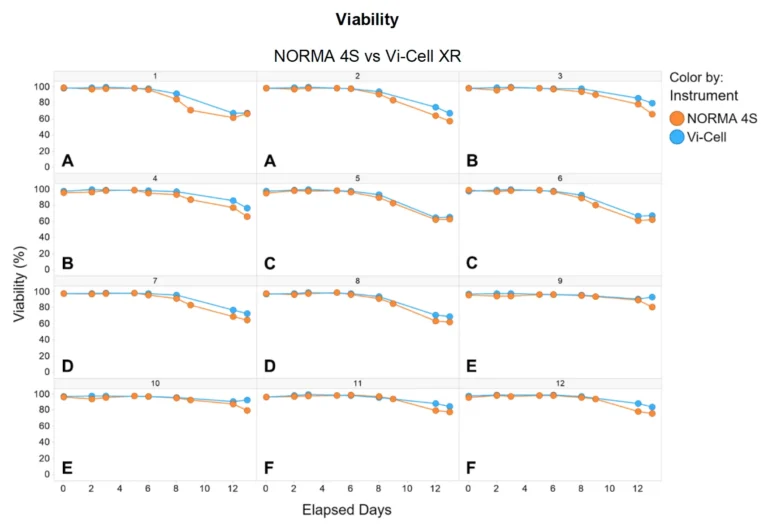

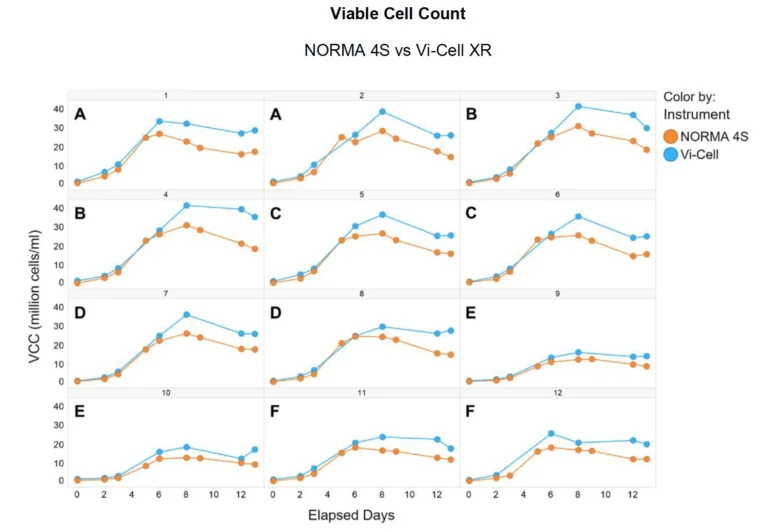

3 - A strong correlation between the NORMA 4S and the Beckman Coulter Vi-Cell XR on 48 bioreactors

A comparative study between the NORMA 4S and the Vi-Cell XR was performed on Ambr® 15 48-way. Six different media conditions were tested in duplicate on one CHO cell line. A sample was taken every day for each condition, except on day 1, 4 and 7. For 48 bioreactors, NORMA 4S measures all bioreactors in less than 1 hour while Vi-Cell XR requires 6 hours. The cell viability and the viable cell count were measured in parallel on both instruments NORMA 4S and Vi-Cell XR.

Results showed a very good correlation between these two cells counters for the cell viability even when the cell viability decreases at the end of the run (Figure 3).

For the viable cell count, results showed a good correlation at the beginning of the run but deviated after day 6 for all matrices. Indeed, the curve corresponding to the measurements taken with the NORMA is slightly lower than the measurements taken with the Vi-Cell the first 6 days, then the difference between the two instruments is a little more pronounced until the end of the run. However, it should be noted that the Vi-Cell used here in this experiment was measuring higher cell counts compared to other Vi-Cells present in the laboratory.

We can therefore observe that, overall, the data obtained by the two instruments are similar.

Figure 3 : Cell viability correlation between the NORMA 4S and the Vi-Cell XR on the Ambr® 15 48-ways. The six feed conditions were performed in duplicated on CHO cells. (Data courtesy of GSK)

Figure 4 : Viable cell count correlation between the NORMA 4S and the Vi-Cell XR on the Ambr® 15 48- ways. The six feed conditions were performed in duplicated on CHO cells. (Data courtesy of GSK)

Conclusion

The NORMA technology is capable of accurately monitoring VCC and viability with a combination of significant advantages like low sample volume, label free detection, and quick measure These advantages in combination with its simplistic design make it a good candidate for very small-scale bioreactors and high-throughput measures. Its high repeatability is also a key parameter in the effort to narrow batch to batch deviations. Moreover, the integration of NORMA 4S with the Sartorius Ambr® 15 allows a total automation of the measurements and to perform many measurements quickly.

Acknowledgements

iConsensus consortium

The project leading to this application has received funding from the Innovative Medicines Initiative 2 Joint Undertaking under Grant Agreement n°777397. This Joint Undertaking receives the support from the European Union’s Horizon 2020 research and innovation programme and EFPIA.

These results are part of a project that has received funding from the Innovative Medicines Initiative 2 Innovative Medicines Initiative 2 Joint Undertaking (grant agreement No 777397 for funding. This Joint Undertaking receives the support from the European Union’s Horizon 2020 research and innovation programme and EFPIA partners Bayer, Byondis, GSK, Pfizer, Rentschler Biopharma, Sanofi and UCB.

ihi.europa.eu Disclaimer: This communication reflects the author’s view and neither IMI nor the European Union, EFPIA, or any Associated Partners are responsible for any use that may be made of the information contained therein.